Heyne & Penke

Almost 120 years of expertise across 25,000 m²

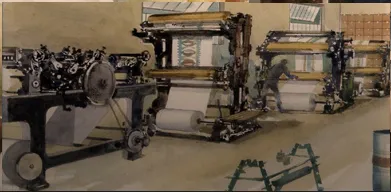

As one of Germany’s leading manufacturers of flexible packaging, we have been your experienced partner for printing and finishing food packaging, as well as packaging in the non-food sector, for almost 120 years.

As one of the few full-service providers in the industry, we offer a comprehensive range of flexible packaging made of paper and film, printed using flexographic and gravure printing processes, as well as finishing services. We use state-of-the-art machinery and plant technology. Certifications such as BRC and ISO 9001:2015 have qualified us for many years.

Numerous long-term international customers appreciate our product quality, technical advice, and absolute reliability.

Ecological aspects are also becoming increasingly important in packaging: it should be as resource-efficient and environmentally friendly as possible. In addition, product protection must still be guaranteed! Heyne & Penke acts in an environmentally conscious manner in all areas of production, as demonstrated not least by our ISO 14001:2015 environmental management certification, which we acquired in 2024.

We are happy to consult you individually with regard to the requirements of your market and work together with you to find the best solutions.

sustainability

Sustainability is important to us.

certificates

Here you can find an overview of our certificates.

contact person

Here you will find the right contact person.

„Flexible and forward-looking, we align future investments and the development of primarily with the requirements of our customers."

Owners and managing directors Peter and Christoph Penke-Wevelhoff

Our company history

For almost 120 years, our company has stood for innovation and quality.

Founded in Holzminden, we have continually developed and eventually relocated to Dassel.

Through massive expansions in space and machinery, we have been able to significantly increase our production capacity

and establish ourselves as a leading provider in our industry.

Discover our company history and learn more about our development.

Founding

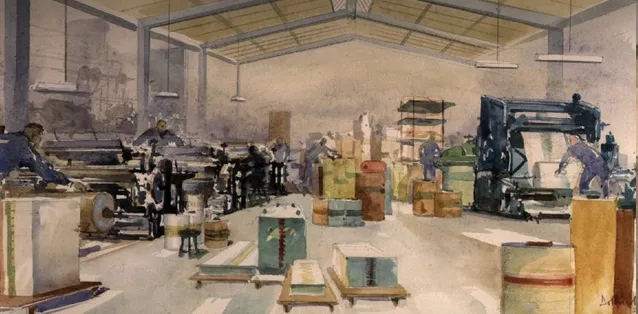

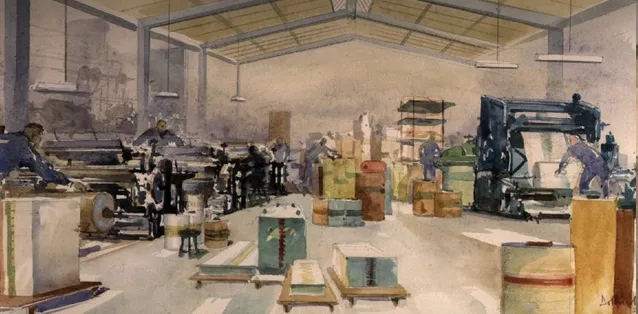

![]()

On July 23, 1906 the company Heyne & Penke was founded by Mr. Benno Heyne and Mr. Heinrich Penke in Holzminden.

factory building

Construction of the first company-owned factory at Sparenbergstraße in Holzminden.

expansion

Massive spatial and machine expansion.

production hall

Construction of another production hall.

renewal

Start of a significant renovation and construction phase.

expansion

New printing machine hall and extension of the administration building at Sparenbergstraße in Holzminden.

Further innovation: the first flexo film printing goes into production.

Company location in Holzminden

Since the location of the company in Holzminden no longer allowed spatial expansion, the acquisition of property in Dassel.

Opening the new factory building in Dassel and putting into operation a new flexographic printing machine.

First certification according to DIN EN ISO 9002.

New development at Heyne & Penke: production of the first transfer pictures/ tattoo series.

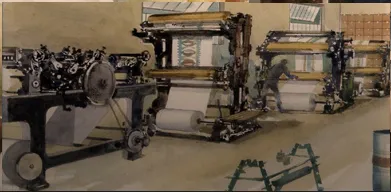

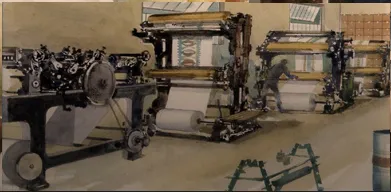

Extension of the second production hall in Dassel. Putting into operation the 8-colour flexo printing machine Stellaflex from Windmöller & Hölscher.

Launch of a regenerative incineration plant with a capacity of 40,000 m3 at the Dassel factory.

Further expansion of the machinery park with a 9-colour gravure printing press Heliostar from Windmöller & Hölscher.

Innovation:

Gravure printing on film makes Heyne & Penke one of the few full-range suppliers in the flexible packaging area.

Certification according to DIN EN ISO 9001.

Expansion of the plant in Dassel for the construction of the third hall.

Putting into operation a Comexi Nexus Dual laminating machine.

From now on, even more efficient production of two-layer composites from different films using solvent-free adhesives up to a maximum laminating width of 1,315 mm.

Extension

Construction of a 350 square metre ink store, expansion of the printing plant by 700 square metres and increase of the laboratory and material testing areas by 120 square metres.

Putting into operation a 10-colour gravure printing machine Heliostar GE10 with inline laminating system from Windmöller & Hölscher.

Investment in a wax coating machine from Kroenert.

With a coating width of 1400 mm, this machine provides high production speed.

This allows applying a double-sided coating in a single operation, if desired, also as a glossy coating.

In February 2008, we were certified by TÜV Nord according to the international standard DIN ISO 22000: 2005. Complex conditions include: strict HACCP principles. HACCP stands for “Hazard Analysis Critical Control Point” and guarantees our customers compliance with food safety regulations.

In Dassel: in July, the ceremony of completing the main structure of halls 4 and 5, and in September – the ceremony of laying the foundation for a new administration building.

Completion of hall 4 (production hall for the slitter and packing)

and hall 5 (warehouse for finished goods and gravure cylinders)

Moving to Dassel

In January 2012, the administration moved to the newly built premises in Dassel. This completed the company’s final relocation from Holzminden to Dassel.

Peter Penke-Wevelhoff, as a General Manager, and Christoph Penke-Wevelhoff, as a Technical Director, took over the management of the company after the death of their father and former company owner Hans-Peter Penke-Wevelhoff.

Putting into operation the new 8-colour flexographic Miraflex printing machine from Windmöller & Hölscher. This machine has 2 additional ink stations for lacquer and varnish applications.

Investment

One million Euro Investment in production technology and environmental protection – construction of a photovoltaic park for own power generation, besides others.

Extension of the production halls

Putting into operation a new 11-colour gravure printing machine Heliostar SL from Windmöller & Hölscher

expansion

Further expansion of infrastructure and machinery park

Expansion of the machinery park

Commissioning of a new automatic slitter from SAGE

and a new flexo printing machine from Windmöller + Hölscher

Installation and implementation of a new shelving and goods storage system

Investion & Zertifizierung

Investment in a new paint mixing plant and new environmental management certification ISO 14001

expansion

Expansion of production with 2 roll cutters, a gravure printing machine and automation of warehousing

Our mission statement

Our company stands for consistency and continuous development. We are actively committed to environmental protection and strive to make our processes sustainable. Quality is our top priority, and we work tirelessly to meet the highest standards.

Proximity to our customers is particularly important to us, because only through close cooperation can we optimally meet their needs. Our employees are the heart of our company; their satisfaction and well-being are important to us.

Ultimately, we strive for healthy profits to secure our future and continue to invest in innovation and growth.

Consistency &is important to us

Historically, we have been building long-term and collaborative relationships with our customers and suppliers through Consistency, Reliability and Predictability. These are also our principles for future business operations. Verbal and written commitments or letters of intent to customers and suppliers are fulfilled by all employees.

Our company focuses on a long-term strategy; however, we regularly check its effectiveness and adapt it to the ever-changing environment.

We are committed to

The aspect of Environmental Protection is now fully integrated into the company’s policy as a matter of course. The products sustainability through employing the latest environmental technology and using resources efficiently is a special focus in all our business and production processes. We maintain ecological standards in packaging production at the highest level, both in terms of recycling materials and reducing energy consumption as much as possible. Environmental responsibility doesn’t cover only technical aspects but also all related organizational processes in the company, as well as consulting customers on specific ecological issues.

We value

Each of our employees is firmly devoted to achieving and ensuring the highest quality and top standards for our products and services. Every employee acknowledges that the guarantee of the final product quality is an all-embracing task across all departments. In terms of our ISO standards, we test the quality of our products not just at the end of the manufacturing process, but we control it right from the beginning. We constantly adopt and endorse the latest technologies and innovations to deliver maximum benefits to our customers.

Our duty is to sustain a profitable company to ensure successful operations for our clients and ensure job security for our employees.

Our company follows the principle of a close partnership with our customers.

This includes, among others:

We handle all sales transactions quickly and to the fullest satisfaction of our customers.

We support our customers in solving technical and commercial problems.

We closely monitor all important trends in the relevant sales and purchasing markets, identify new technical- and consumer- related market developments at their early stage and effectively respond by introducing product improvements, product innovations, modifications in technical and organizational procedures and new purchasing arrangements.

Our employees are the of the company

We believe in our employees and respect their individuality. We value high levels of employee performance, integrity and complete loyalty to the company. We support efficient and motivated employees.