Heyne & Penke has the latest machinery and equipment technology for delivering superior print quality

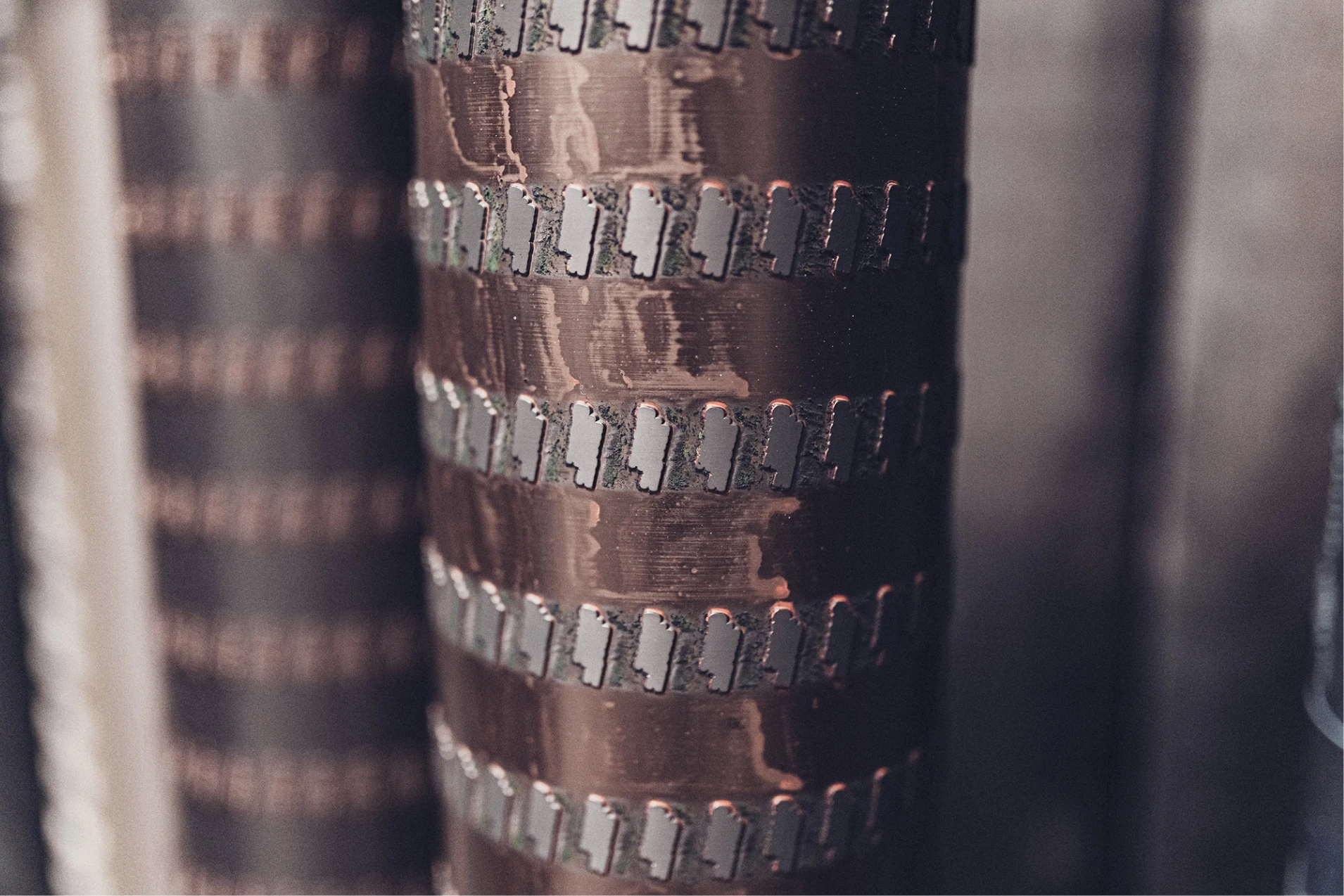

Gravure Printing

In the gravure printing process, the print image information is mechanically or laser engraved into copper cylinders, typically using the CMYK color scale. Additionally there could also be some spot colours (for example, in the logo). At Heyne & Penke, we print in up to 11 colors on print widths of up to 1320 mm, with options for reverse-side printing and inline lamination.

Gravure Printing Capabilities

Cold-seal & hotmelt coating (facon)

Inline lamination

Flexographic Printing

The flexographic printing process is a high pressure process using flexible printing plates.

The printed image information is transferred as an imprint onto a rubber or photopolymer plate. These printing plates are glued to a sleeve.

Flexographic Printing Capabilities

Printing Processes

Gravure & flexographic printing process

Production Area

25.000 m²

Flexographic printing presses

2

Converting & finishing machines

3

Reel slitters

5

Gravure printing presses

3

Finishing & Converting

High-performance technology, expertise, and flexibility in the finishing of films and papers of various grades.

Finishing & Converting Capabilities

We hold an area for 4,500

customer pallets and 10,000

printing cylinders